Application Requirements

더욱 포괄적으로 이해하기 위해, 우리는 애플리케이션 요구 사항을 다음 섹션으로 분류했습니다.

Simple vs Complex Scenarios

3PL(제3자 물류)에서는 팔레트에 단일 SKU(재고 관리 단위)를 적재하는 경우가 많습니다. 품목은 대개 라벨이 인쇄된 골판지 상자입니다. 시각적으로 보면 이는 비교적 간단한 시나리오입니다. 하지만 팔레트가 거의 비어 있을 때 장거리 운송이나 상자의 반사 표면과 같은 과제가 여전히 남아 있습니다. 상자에는 아트워크가 있거나, 반짝이고 반사되는 테이프로 밀봉되어 있을 수 있습니다.

예를 들어, 식료품 물류는 더 많은 어려움을 겪고 시나리오도 더 복잡합니다. 혼합 SKU(재고 관리 단위) 시나리오의 팔레트에는 상자, 봉지, 병, 캔, 병 등 다양한 모양, 크기, 재질의 품목이 담겨 있습니다. 재질에는 골판지, 플라스틱, 유리 또는 금속이 포함될 수 있습니다. 품목은 빽빽하게 쌓인 것부터 느슨하게 정리된 것까지 다양한 형태로 쌓이는 경우가 많습니다.

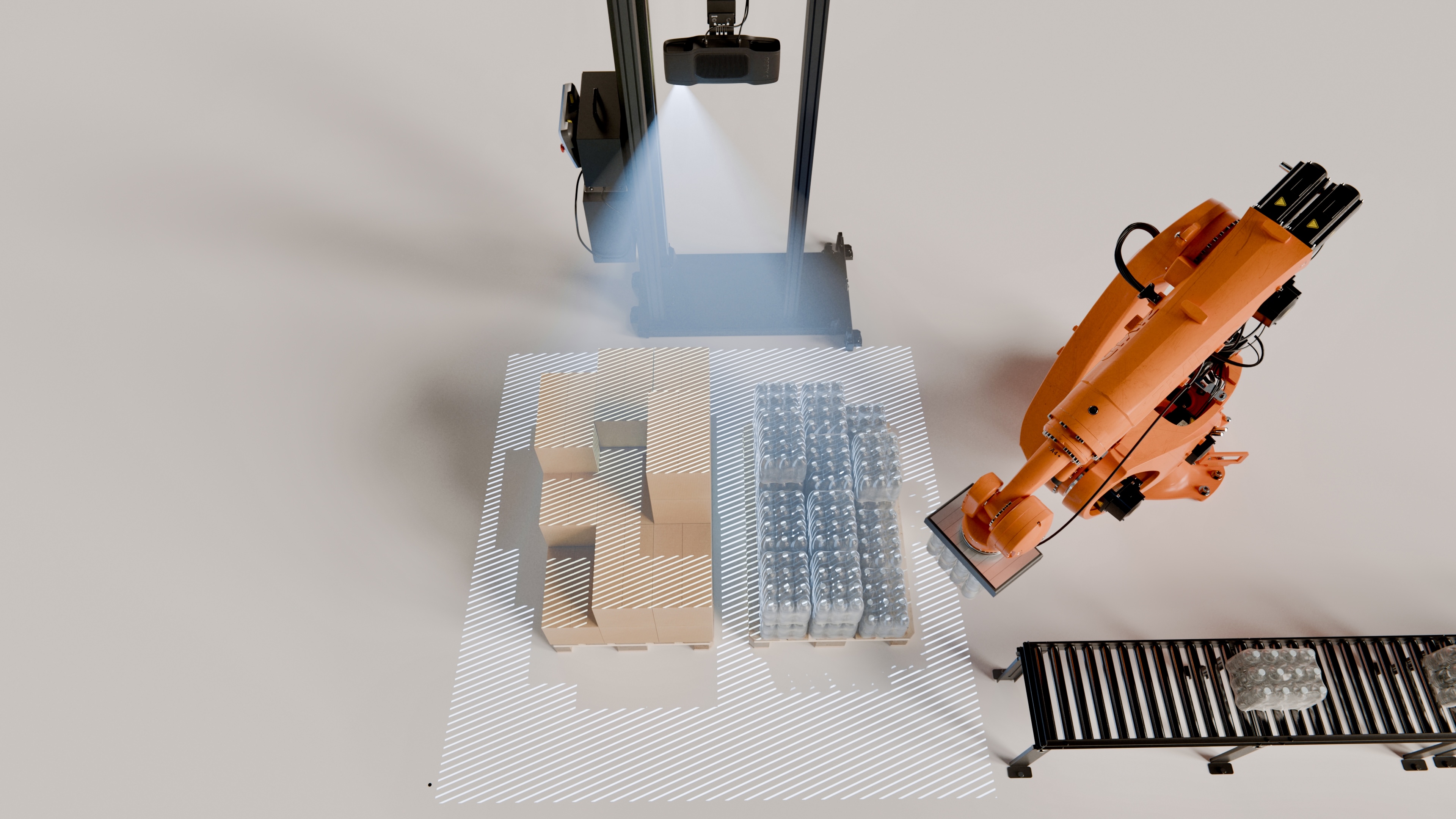

다음 이미지에서 왼쪽은 간단한 시나리오이고, 오른쪽은 더 복잡한 시나리오를 모두 볼 수 있습니다.

Depth

팔레트를 최대한 활용하고 팔레트당 품목 수를 극대화하기 위해 품목을 최대한 높이 적재하는 경우가 많습니다. 이는 일반적으로 팔레트가 보관되는 장소(운송 중 포함)와 적재물의 안정성에 의해서만 제한됩니다. 일반적으로 적재물의 최대 높이는 2.0~2.5m입니다. 고정식 카메라 설정의 경우, 카메라는 최소 1.5m에서 최대 4.5m까지 데이터를 수집할 수 있어야 합니다. 이 모든 범위에서 고품질 3D 데이터를 얻을 수 있어야 합니다.

또 다른 문제는 레이어 깊이입니다. 레이어 깊이란 가장 높은 항목의 상단에서 가장 낮은 항목의 상단까지의 거리를 의미하며, 픽킹이나 배치 작업 중 언제든지 확인할 수 있습니다. 이 차이는 고품질 3D 데이터와 오클루전 모두에 어려움을 줍니다. 가장 높은 레이어의 항목이 아래쪽 레이어의 항목을 가릴 수 있습니다. 카메라의 기준선이 클수록 오클루전 문제가 더 심각해집니다.

Palletization vs Depalletization

품목은 팔레트에 추가되거나(팔레타이징) 팔레트에서 제거됩니다(디팔레타이징징). 두 가지 시나리오는 각기 다른 과제를 안고 있습니다.

팔레타이징에서는 배치 가능한 위치를 정확하게 파악할 수 있도록 포인트 클라우드가 정확하고 완전해야 합니다. 접근 불가능한 영역으로 오인될 수 있는 아티팩트가 없어야 합니다. 또한, 가능한 위치의 수를 최대한 확보할 수 있도록 오클루전을 최소화해야 합니다.

팔레트 제거 작업에서는 안전한 파지점을 찾는 것이 더욱 중요합니다. 안전한 파지점이란, 흡착 컵이 누출 없이 진공을 유지할 수 있는 실제 표면을 나타내는 지점을 의미합니다. 또한, 품목의 질량 중심 근처에 있는 지점을 의미합니다. 중복 피킹을 방지하기 위해 파지점이 품목의 가장자리를 피하는 것도 중요합니다. 이는 잘 분할된 물체와 완전하고 정확한 포인트 클라우드의 조합입니다.

분할은 종종 컬러 이미지에서 수행됩니다. 즉, 컬러 이미지도 고품질이어야 하며 포인트 클라우드에 쉽게 매핑되어야 합니다.

Cycle times

(디)팔레타이징 작업에서는 로봇이 팔레트에서 물건을 집어 올리고 팔레트에 놓을 수 있는 작업 범위를 확보하기 위해 일반적으로 더 큽니다. 따라서 로봇은 부품 집기 작업보다 속도가 느린 경우가 많습니다. 그러나 처리량 극대화를 위해서는 사이클 시간이 여전히 중요합니다. 로봇 사이클은 일반적으로 4초에서 10초 사이이며, 로봇당 시간당 약 1,000개의 품목을 집기하는 속도에 도달합니다. 로봇이 품목을 배치하는 동안 비전 시스템은 로봇이 돌아오기 전에 다음 집기 자세를 캡처, 처리 및 계산해야 합니다. 따라서 부품 집기 작업보다 시간 예산이 덜 엄격하지만 여전히 중요합니다. 카메라 시간 예산은 일반적으로 500ms 에서 1,500ms 사이입니다.

Gripper compliance

포인트 클라우드의 품질은 종종 사용되는 그리퍼 유형을 결정하는 요인입니다. 예를 들어, 포인트 클라우드 데이터의 정확도가 매우 높으면 컴플라이언스가 낮은 그리퍼를 사용할 수 있으며, 이는 일반적으로 더 빠르고 정밀합니다. 완전한 포인트 클라우드는 비전 알고리즘이 그리퍼가 잡을 수 있는 충분한 표면적을 확보하여 더 정확한 파지 지점을 계산할 수 있도록 합니다.

(디)팔레타이징 작업에는 물체, 모양, 크기, 재질이 매우 다양하기 때문에 흡착 컵이 일반적으로 사용됩니다. 이러한 추가적인 유연성은 물체에 닿지 못하거나 충돌하여 물체나 그리퍼가 파손될 가능성을 최소화합니다. Dimension Trueness, 점 정밀도, 평면도는 그리퍼에 필요한 유연성 수준을 결정하는 다른 요소입니다.

(디)팔레타이징에서 품목은 종종 무거워서 그리퍼가 흡입 컵과 기계적 옵션(예: 클램프 또는 트레이)을 모두 갖춘 하이브리드 그리퍼인 경우가 많습니다.

모션 플래닝 및 충돌 방지

(디)팔레타이징에서 고려해야 할 또 다른 요소는 동작 계획 및 충돌 회피입니다. 동작 계획은 로봇이 픽앤플레이스 작업을 수행하는 동안 궤적을 최적화하여 사이클 시간을 절약하는 데 사용됩니다. 케이지 벽, 현재 피킹되지 않는 물체, 그리고 팔레타이징 작업에서 팔레트 위의 다른 물체와 같은 환경적 제약 조건과 같은 장애물과의 충돌을 방지하기 위해 충돌 회피와 함께 사용되는 경우가 많습니다. 비전 시스템이 인식하는 장애물은 로봇이 회피합니다. 이상적인 환경에서는 비전 시스템이 환경을 있는 그대로 정확하게 중첩하여 표현해야 합니다. 그러나 아티팩트가 발생할 수 있습니다. 이러한 아티팩트는 현실 세계와 일치하지 않는 허위 또는 누락된 데이터로 구성됩니다. 예를 들어 허위 데이터는 현실에 존재하지 않는 유령 평면이나 떠다니는 덩어리로 인식되는 반면, 누락된 데이터는 포인트 클라우드의 구멍으로 인식됩니다. 후자는 표면 커버리지가 불완전하여 발생하며, 포인트 클라우드에 존재해야 하는 데이터로 구성됩니다. 아티팩트로 인해 충돌 회피가 로봇의 목적지 도달을 방해할 수 있습니다. 따라서 동작 계획에서는 어떤 장애물을 무시해도 안전한지, 어떤 장애물을 무시할 수 없는지를 정의해야 합니다. 카메라에서 수집되는 3D 데이터의 품질이 향상됨에 따라, 그리퍼 컴플라이언스 및 충돌 회피를 고려한 동작 계획의 복잡성을 줄일 수 있습니다.

요약하자면, 더 높은 품질의 3D 데이터를 사용하면 로봇 작동이 더 빠르고 안전해지며, 결과적으로 처리량이 증가합니다.

이 섹션에서는 (디)팔레타이징 요구사항을 검토했습니다. 이제 다음 단계는 장면의 부피에 따라 select the correct Zivid camera 입니다.