Camera Selector based on Scene Volume

This section aims to help you choose the correct Zivid camera based on the length, width, height, and number of pallets or containers in the scene. The typical pallets that are used for (de-)palletization are Euro pallet (EPAL-1), US standard pallet, and Asian standard pallet. In addition you will find various containers placed on top of the pallets to hold the items.

Pallet Sizes

Dimensions |

||

|---|---|---|

Length |

Width |

|

EUR / EPAL-1 |

1200 mm |

800 mm |

EPAL-2 / ISO2 (UK) |

1200 mm |

1000 mm |

US Standard |

1219 mm |

1016 mm |

Australian Standard |

1165 mm |

1165 mm |

Asian Standard |

1100 mm |

1100 mm |

The height of the contents on the pallet depends on the application. It is a function of stability during transport and storage, the type of items, and how they are packed. For shrink-wrapped items, the height can be up to 2.2 m. Maximum height is typically limited by the height of containers and trailers, which is around 2.6 m. For loosely packed items, there is typically a bin on the pallet, and the height of the contents is typically between 0.5 m and 1.5 m.

Camera Selector

Choose whether you have a stationary or an on-arm camera.

Zivid 3

The aspect ratio of Zivid 3’s field of view is 1:1. In the following table we have added ~10 cm margin to both length and width of the pallets.

Distance to top-layer

EUR / EPAL-1

2000 mm

US Standard

2000 mm

Asian Standard

1900 mm

Zivid 2+ LR110

The aspect ratio of Zivid 2+’s field of view is 4:3. In the following table we have added ~5 cm margin to both length and width of the pallets.

Distance to top-layer

EUR / EPAL-1

1300 mm

US Standard

1400 mm

Asian Standard

1500 mm

Considerations taken for Camera Selector

Stationary mounting

The camera must be mounted high enough to see the full top-layer of the pallet. Typically this would be sufficiently high to allow robot to pick from the top layer without colliding with the camera. If not you must consider mounting the camera even higher.

You should also consider the tolerance in how the pallet is placed under the camera. If the pallet can be misaligned, you must ensure that the camera’s field of view covers the entire top-layer even in the worst-case misalignment.

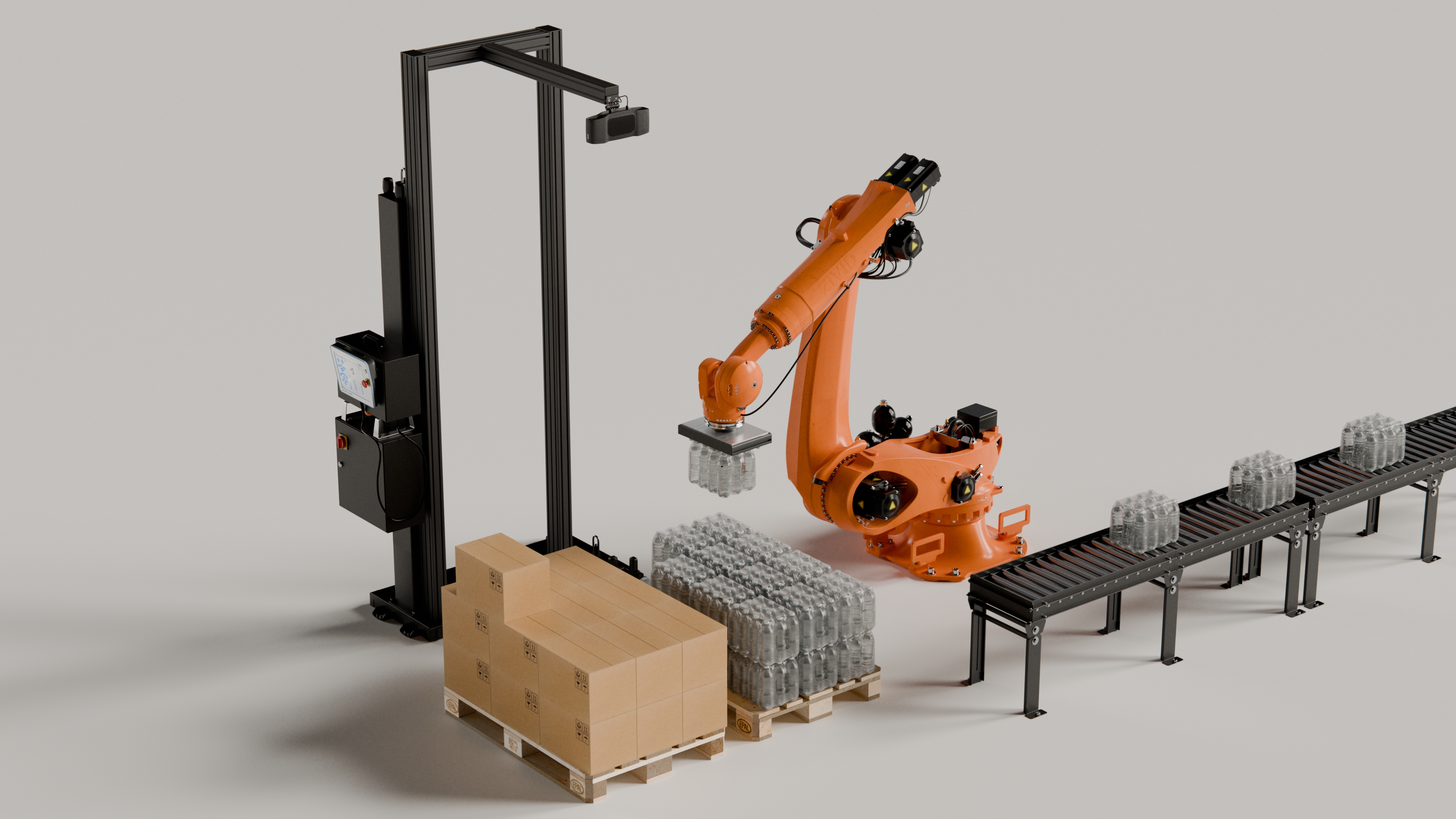

On-Arm mounting

The camera has to be mounted on a robot in such a position that it can see the entire length and width of the current top-layer during capture. At this position, the gripper needs to be entirely outside of the camera’s view of the top-layer.

One benefit of the robot mounted scenario is that the absolute height can be adjusted as layers on the pallet is removed (or added). The camera should always be positioned such that it can see the entire top-layer, but not much more.

Spatial resolution

Spatial resolution is an important factor when selecting the distance of imaging. To find spatial resolution requirements, we need to consider the smallest object feature to be seen at the largest desired distance of imaging. As an exercise, let us take a cube of 3 cm x 3 cm in size. A spatial resolution of 2 mm gives ~15 points in each dimension, which is ~225 points. This number of points should be sufficient to detect the object from the point cloud and estimate its pick pose.

The next section is about the correct positioning of the camera for the best imaging results.