Bin Picking & Machine Tending Tutorial

Random or automated bin picking is typically at the input stage of a manufacturing system in automotive, white goods, mechanical assembly, or machine tending factory automation solutions. This type of robot picking application often contains only one type of part with a specific purpose rather than general goods. Go to our Bin Picking & Machine Tending pages to read more about it, confirm it is your application of interest and understand why Zivid cameras are a good fit. In this application, vision and software enable a robot to pick objects from a bin or a pallet. If you want to learn how to get the maximum out of a Zivid camera for bin picking and machine tending, then this tutorial is for you.

Application Requirements

In the Application Requirements section, we provide an overview of typical scenes and objects in bin picking that are challenging for imaging and getting good 3D data. We explain which essential object features a camera needs to see to successfully detect the objects of interest and estimate their pose.

Camera Selector

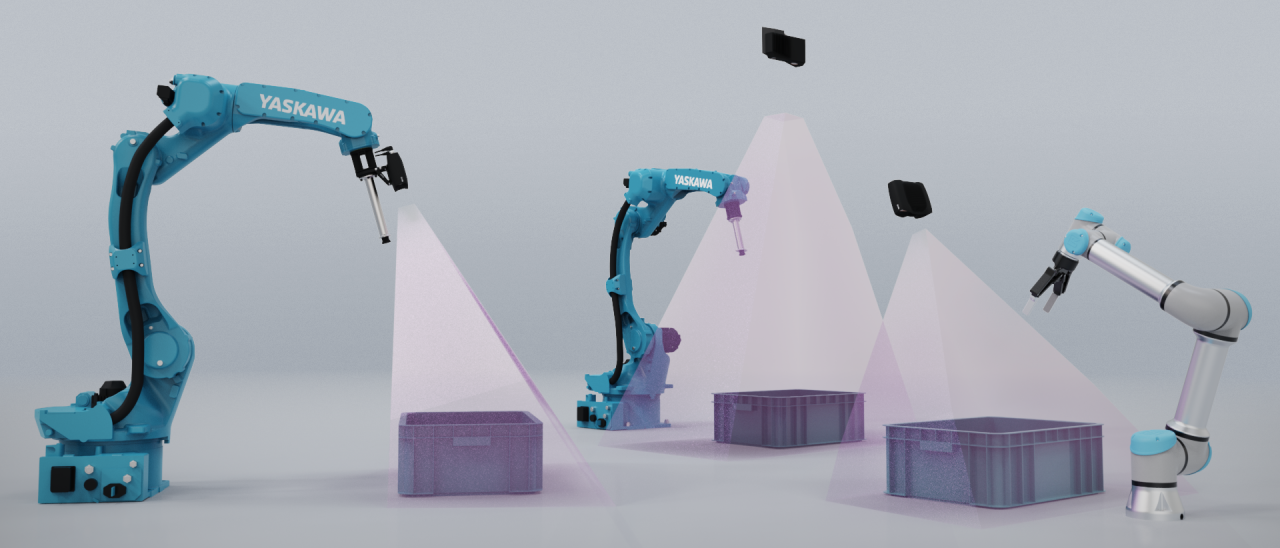

The section Camera Selector based on Scene Volume provides detailed guidance on which Zivid camera model to select. We cover the typical type and size of bins in the scene and important considerations for on-arm and stationary camera mounting. This includes, for example, robot clearance distance for stationary mounting and the distance between the gripper tip and the camera for on-arm mounting.

Positioning Correctly

In the Positioning Correctly section, we cover the positioning of the camera for the best imaging results.

Settings Selector

This section provides detailed guidance on the best camera settings based on your time budget from the moment you trigger an acquisition until you get the point cloud. Here we also consider your PC specs because data transfer and point cloud processing depend on that as well.

Optimizing Robot Cycle Times

In this section, we explain how to optimize your robot cycles for speed by making use of multithreading. The focus is on the best practices for scheduling robot motion and capturing and processing the point cloud to get a pick pose. We cover both stationary and on-arm mounted applications.

Production Preparation

The following section covers machine vision processes to help you prepare your camera for production. We include camera warm-up, infield verification and correction, which we advise doing before deploying the camera, as well as hand-eye calibration, which is an essential process. We also cover downsampling, transforming, and ROI BOX filtering of the point cloud to reduce the number of points and thus reduce the processing time on your side.

Maintenance

Lastly, the Maintenance section covers specific processes we advise carrying out to ensure that your bin picking cell is stable with minimum downtime.

Click Next to read the Application Requirements.