Mechanical Interface

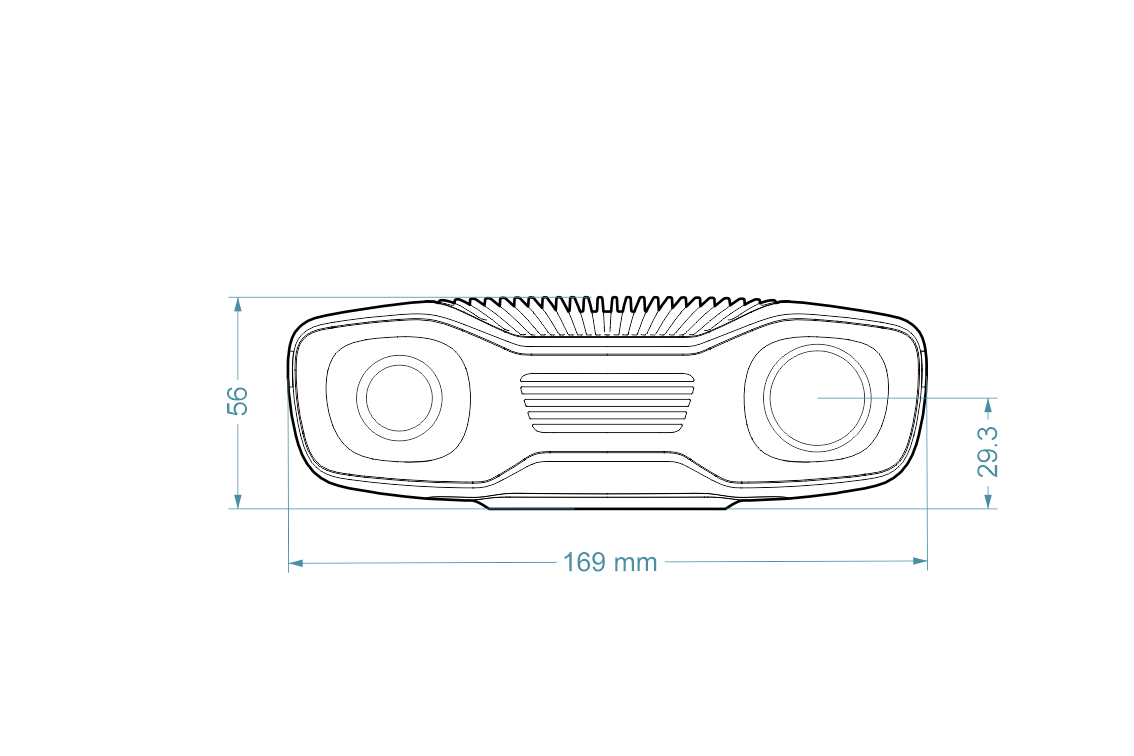

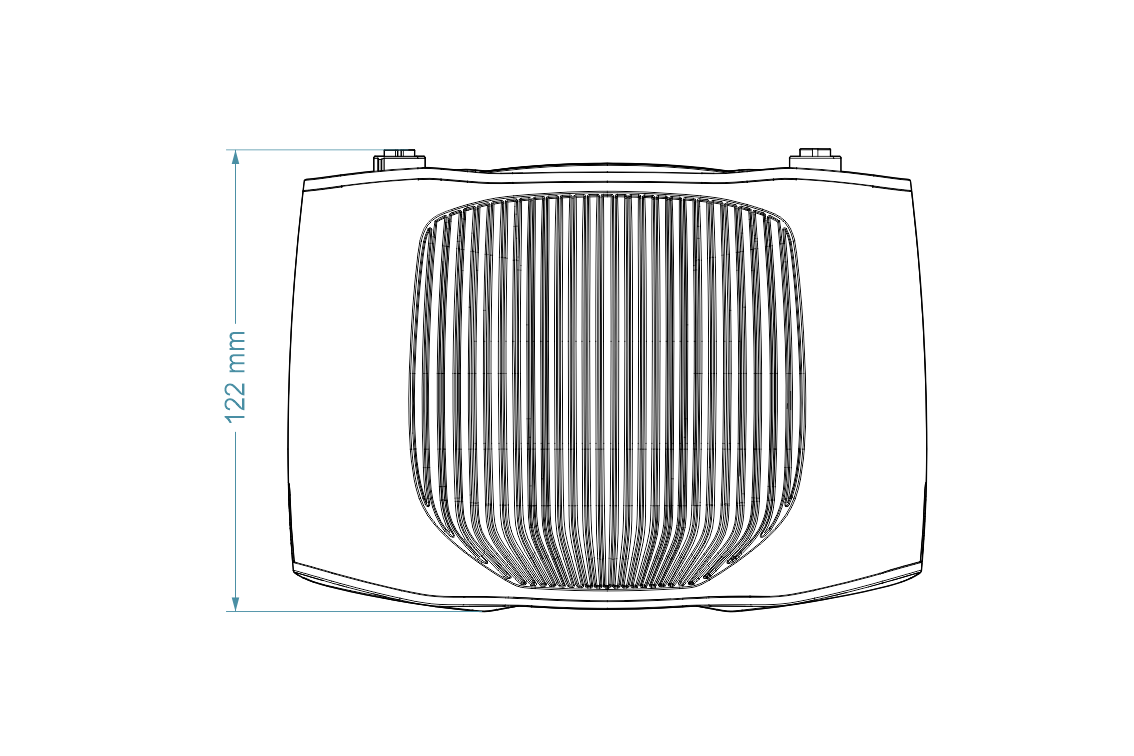

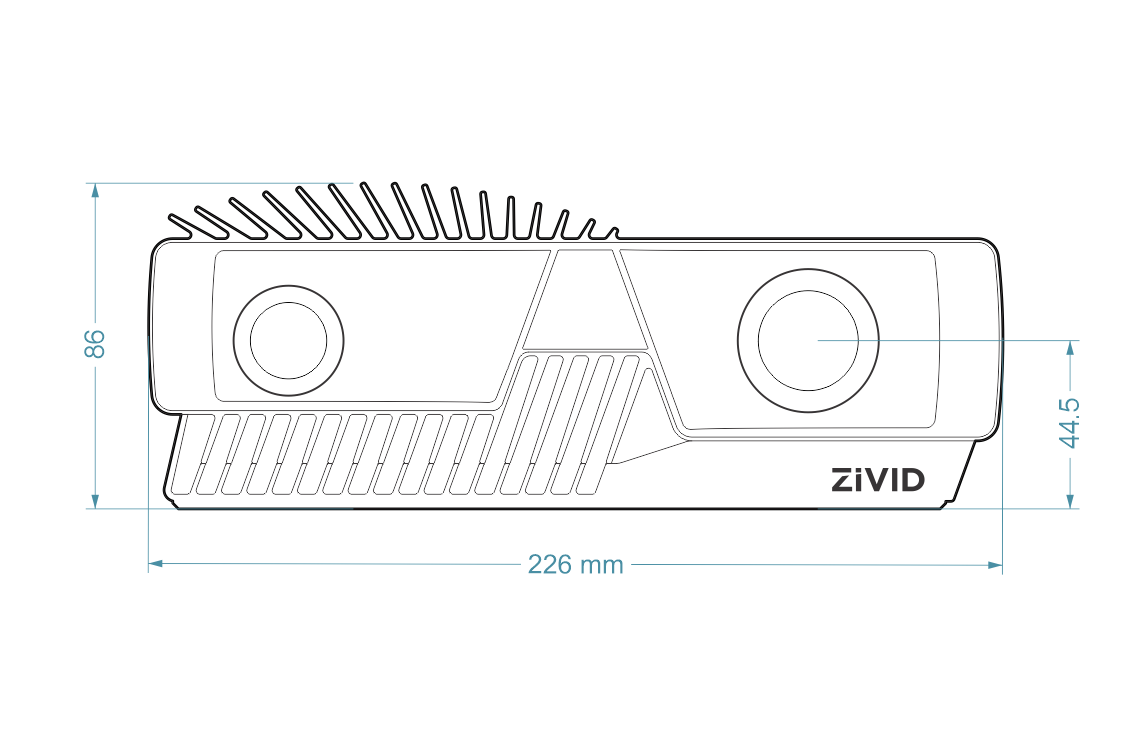

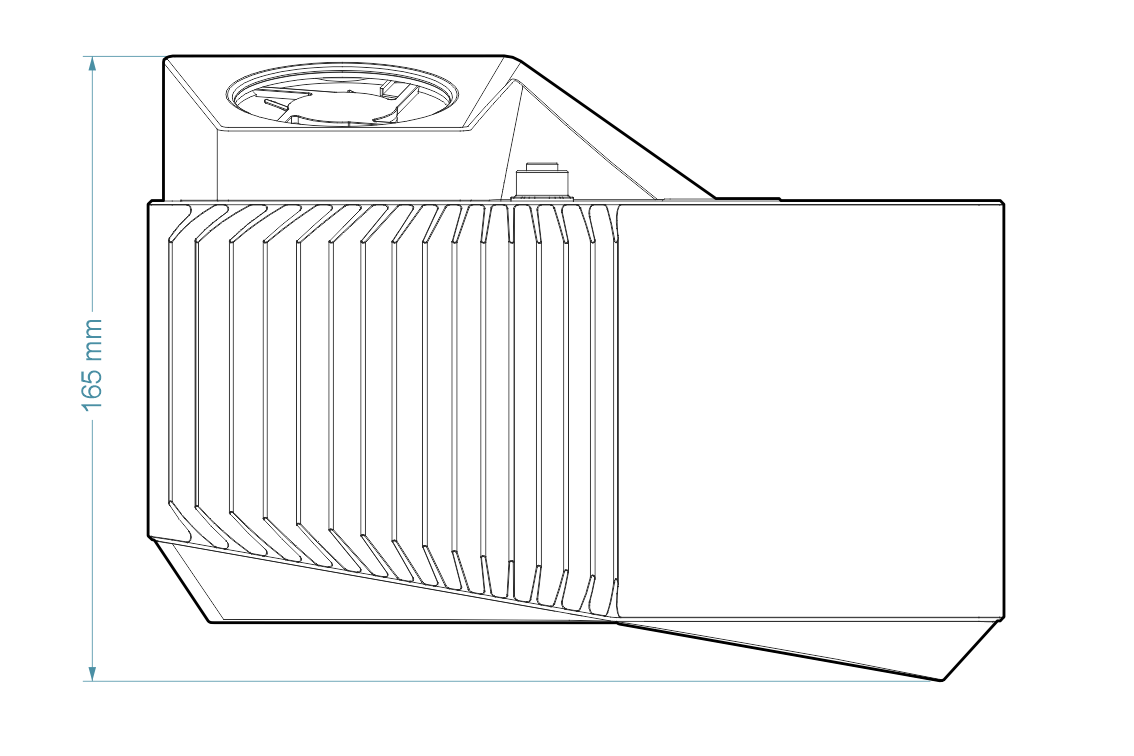

Dimensions

Mounting Specifications

The Zivid Two camera has three M5 mounting holes, one Ø5 positioning hole, and one Ø5x1 obround alignment hole. We recommend using DIN 912 / ISO 4762 Hexagon or ISO 14579 Hexalobular socket head cap screws in stainless steel (A2 or A4). To ensure not to damage the threads, we recommend not exceeding the specified maximum torque value when fastening the screws.

Flatness of Mounting Surface

For optimal performance we recommend a mounting surface flatness of ±0,05 mm or better. Mounting the camera to an uneven surface can in some cases affect the calibration.

We recommend using one of the Zivid Camera Mounts to ensure problem free installation of the camera.

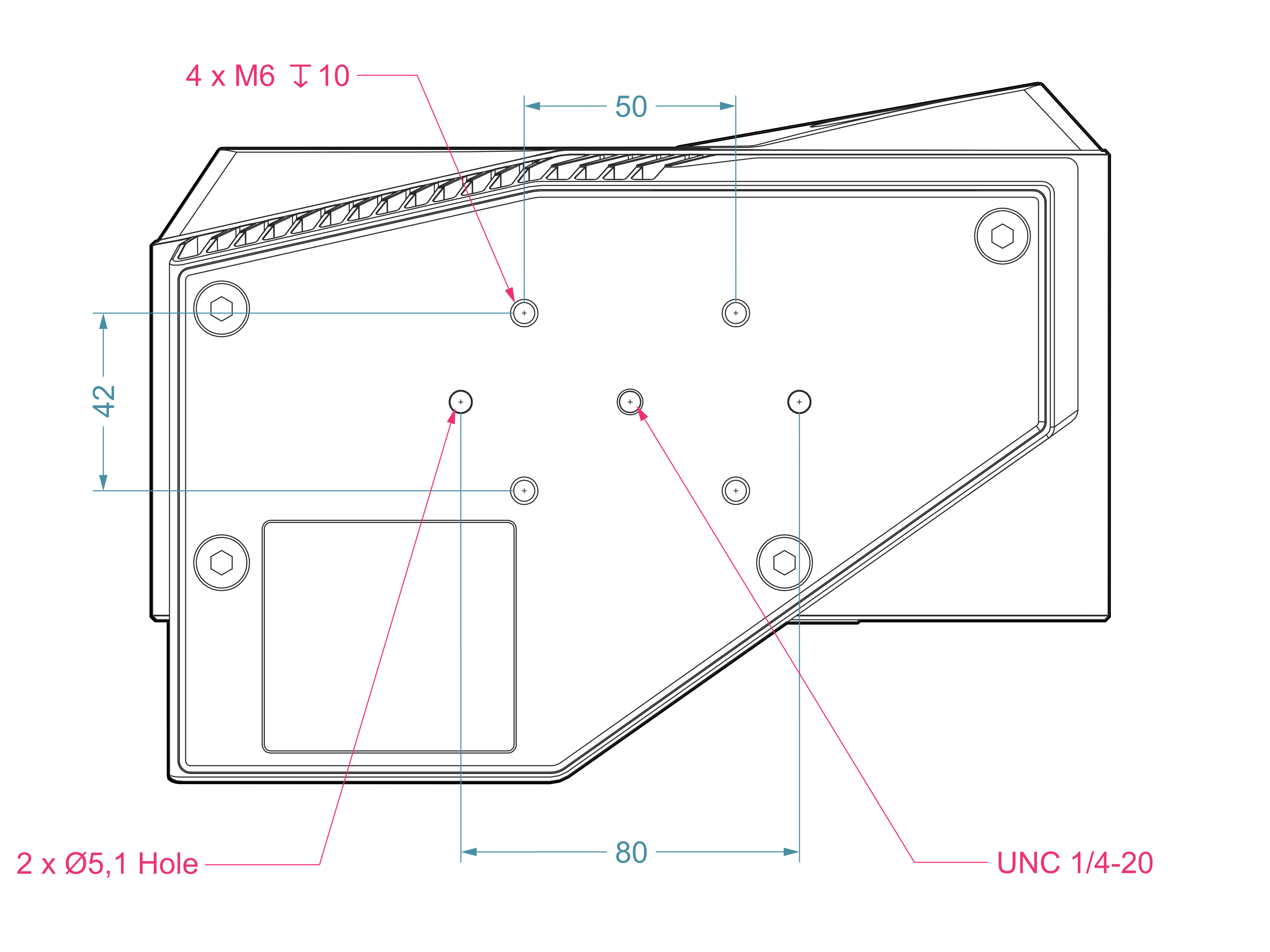

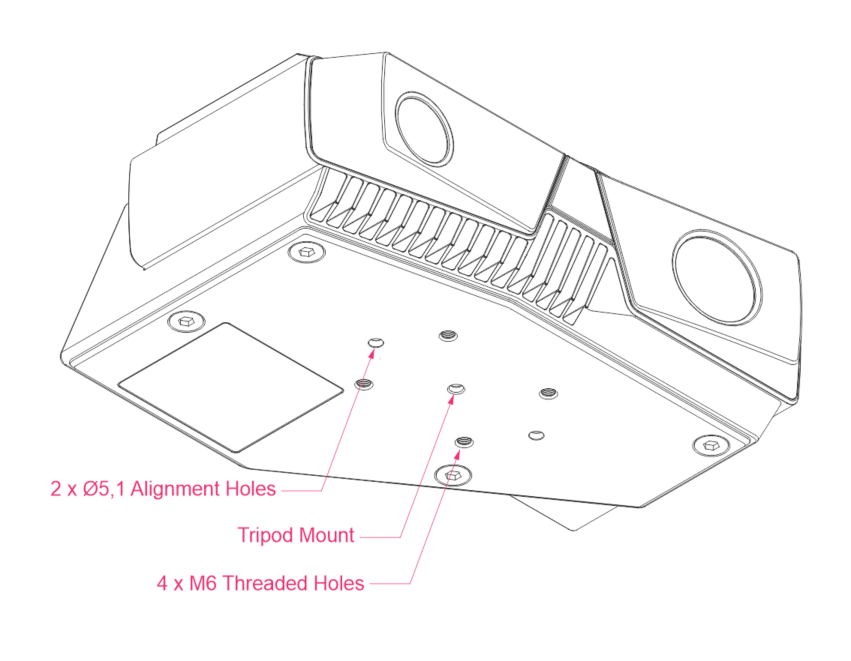

The Zivid One+ camera has four M6 mounting holes and two Ø5 alignment holes. Use the threaded holes on the bottom side of the device to mount it to a bracket. We recommend using DIN 912 / ISO 4762 Hexagon or ISO 14579 Hexalobular socket head cap screws in stainless steel (A2 or A4). To ensure not to damage the threads, we recommend not exceeding the specified maximum torque value when fastening the screws (5 Nm).

Continue reading to find out more about Mounting options for Zivid cameras.