Using Zivid Inside Protective Housing With Glass Window¶

Introduction¶

Zivid 3D cameras are rated with IP65 or higher, which means that they can withstand dust and water without taking damage. However, the camera could be used in extra harsh environments. It could, for example, be exposed to one or more of the following:

weld fumes

paint

excessive heat

other elements

Then a natural question arises; should the camera be put inside some form of a protective housing?

Tip

For protection against unforeseen accidents we provide a Protective Cage for Zivid Two.

We will address several aspects that follows if the Zivid camera is to be built into a protective box. We will address considerations around optical conditions, temperature, condensation, general maintenance, and ruggedness.

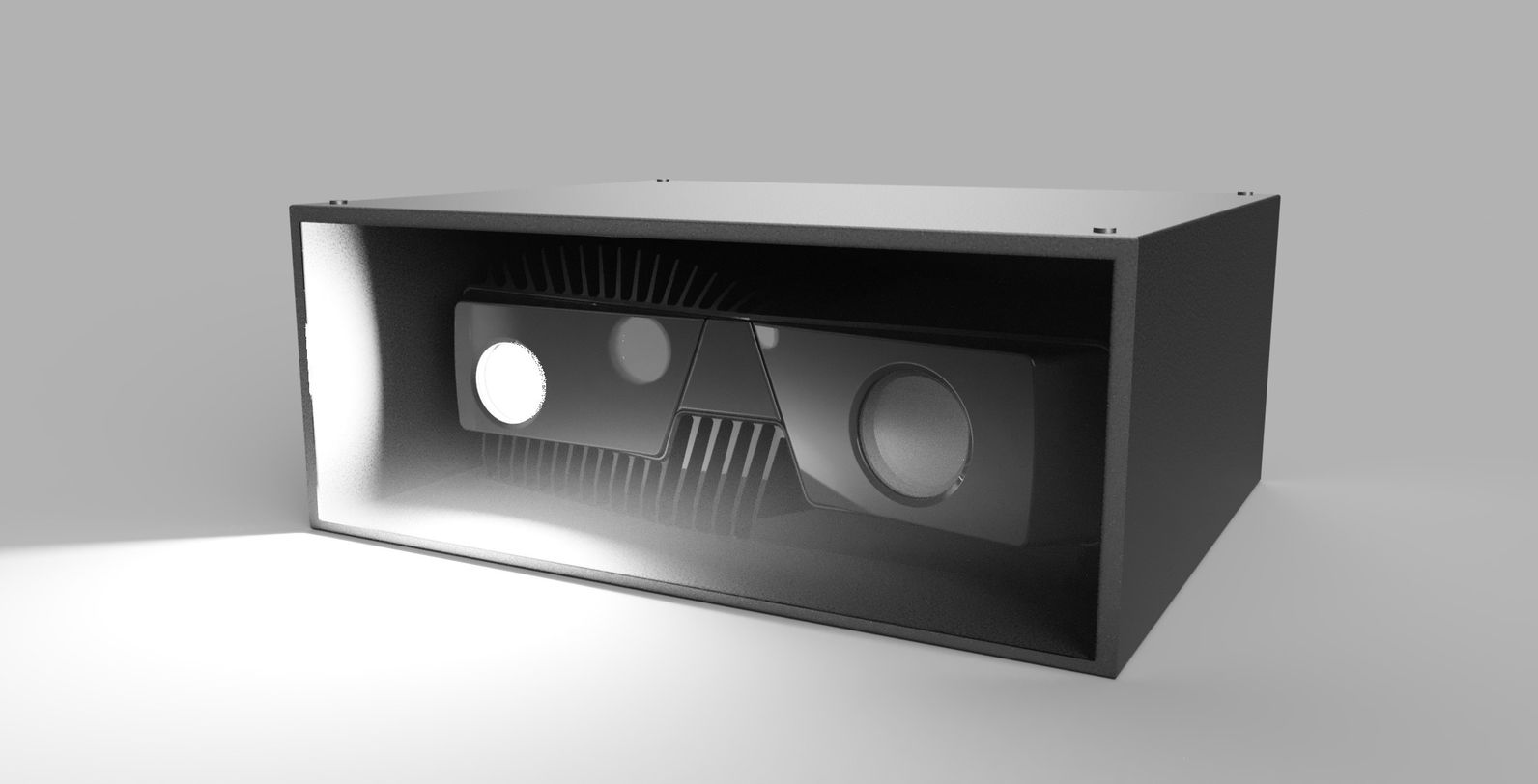

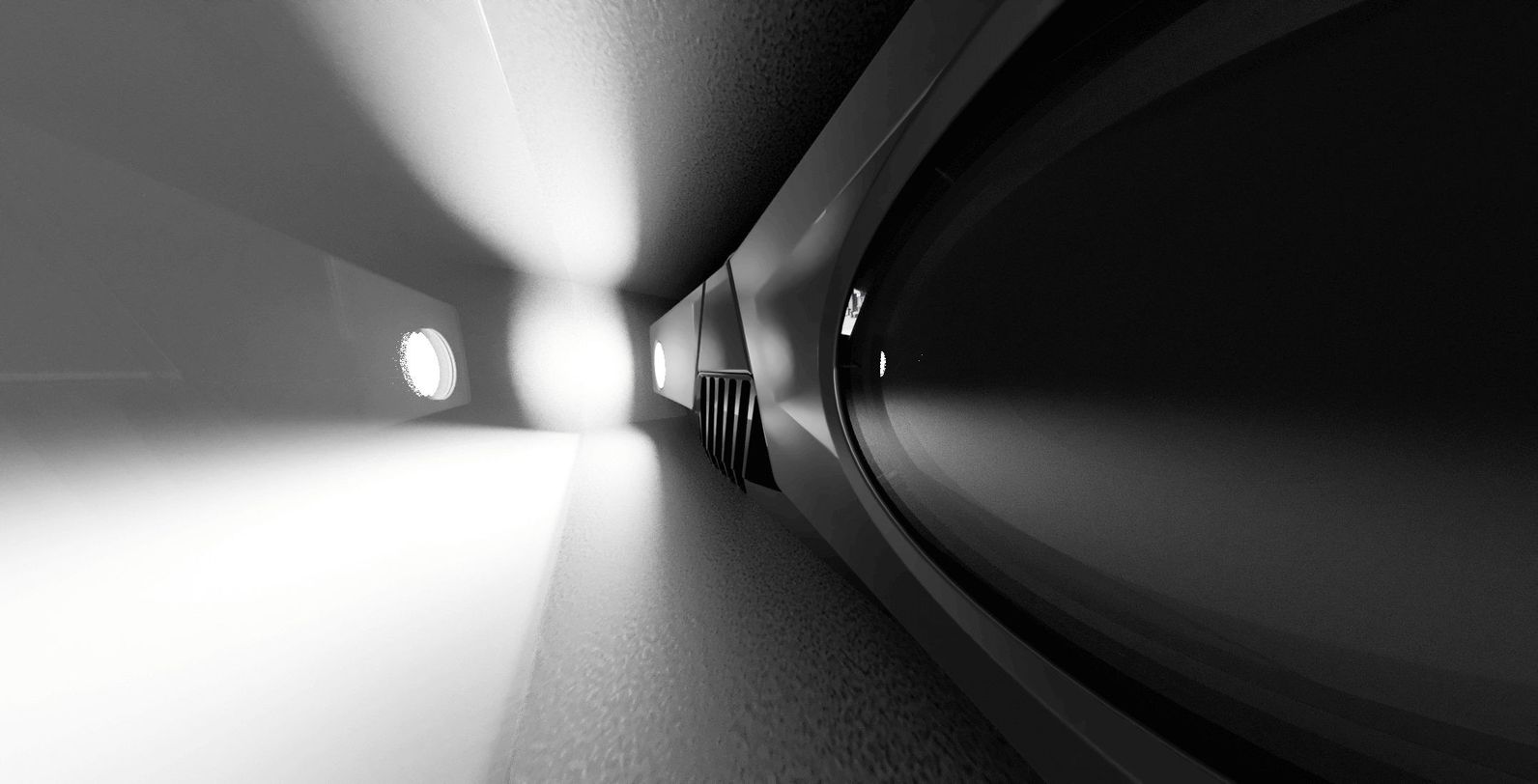

Designing a protective housing¶

For the following we assume that our sensor house will contain some protective glass for the sensor to look through. Note that in some applications it is also possible to leave the front side open. In this case one can use high pressure air inside the housing to prevent dust or other particles from entering through the opening. For now, we will assume that we will build a functional protective housing for the Zivid 3D camera that includes the following essentials:

- Windows or looking glass

For the Zivid sensor to look out from. The smaller the size of these windows the better in terms of backlight reflections, given that they do not cause shadow regions in the camera or projector field of view.

- Protective walls.

For example made in aluminum or plexiglass.

- An opening

For feeding in necessary cables and connectors.

- A mounting solution

Here the protective housing typically would be sandwiched between the Zivid camera and the mounting position where the camera is going to be.

Note! The position of the camera relative to the protective window may change the optical performance. This may in turn impact the accuracy of the Zivid point cloud. Keep the camera rigidly attached to the box to reduce this risk.

- Temperature and humidity control

To control temperature and humidity inside the camera housing. This can be passive if the external environment influence and the workload of the camera are such that and the temperatures inside the housing do not overheat it. If the ambient temperatures in the workspace of the camera exceed the limits defined in the Zivid camera datasheet then there is a need for active regulation.

Next, we will dig a little deeper into the various challenges that need to be addressed.

Temperature, humidity, and maintenance¶

When boxing in the Zivid camera it is important to consider the thermal conditions inside the housing during operation. Let us look at a few considerations:

The temperature inside the housing should match the datasheet of the Zivid 3D camera. For example, for Zivid One+, the camera is rated to operate between 10 to 40°C (see datasheet). The camera is specified to provide full performance within this temperature range. Consequently, there is a chance that the accuracy of the camera will drift if the camera is used outside of this range. In the worst case, the camera could be damaged from working under too high temperature.

The air inside the housing (and camera) should be dry. This is to prevent condensation from forming on either the Zivid camera’s lenses or the inside of the window (or the looking glass of the sensor).

The temperature inside should be similar or slightly higher than outside of the housing to prevent condensation from forming on the window.

You might have noticed that your photographic camera struggles to get clear images if you try to take an image out of a cafe window on a rainy day. Similarly, condensation or dust on lenses, filters, and windows that obstruct the Zivid camera’s view may result in degradation of 3D point cloud quality. Therefore, it is recommended to keep housing windows and camera lenses clean.

Caution

Be sure to use cleaning equipment intended for cameras when cleaning the Zivid’s camera lenses and housing windows, such as long fiber cloth or paper. Avoid wiping too hard on the lenses directly when cleaning it. A tip is to apply the same pressure as you would when operating your smartphone.

Image of a person seen through a condensed window. (photo by Matteo Catanese on Unsplash)¶

In the unlikely event that humid air gets trapped inside the camera house, condensation may form on the lens. This could happen if the camera is stored (unplugged) in a humid and cold environment. To get rid of the condensation, place the camera in a cold and dry environment and leave it powered but with the USB disconnected (open air hole) for two days. The condensation will evaporate and disappear.

Lastly, it is recommended to design the camera housing so that the window does not move relative to the camera. This is for optical reasons that will be addressed next.

Choosing the right glass¶

Light will change its path when passing through glass, therefore it is important that the window is of optical quality so that the camera accuracy is not altered. Optical glass is typically defined by its refraction index, Abbe number, and absorption rate. For the window to serve the purpose of protecting the camera, and not alter the light, it should:

be very flat and even

have a low refraction index

have high Abbe number

have low absorption rate.

It is recommended to consult an optical glass specialist when procuring the window.

Tip

The glass should have a low refraction index, high Abbe number, low absorption rate and have a high degree of evenness and flatness.

Caution

Typical glass windows in buildings have a high absorption rate which will negatively impact signal-to-noise-ratio if used to protect a 3D sensor.

Zivid recommends window thickness between 1-5mm. Higher thickness may also work fine, but Zivid has not performed experiments with thicknesses exceeding 5mm.

Finally, the window should be positioned close to the camera lens and be aligned more or less parallel with the camera.

How does the glass thickness affect camera performance?¶

By following the guidelines above, placing a window in front of the Zivid camera will have a negligible impact on the performance for most applications. Before putting the system into production it is highly recommended to verify stable performance and compare performance with and without the protective housing in terms of point cloud accuracy.

Tip

Verify the quality of the protective glass window by comparing at least two point clouds of the same reference object under the same conditions.

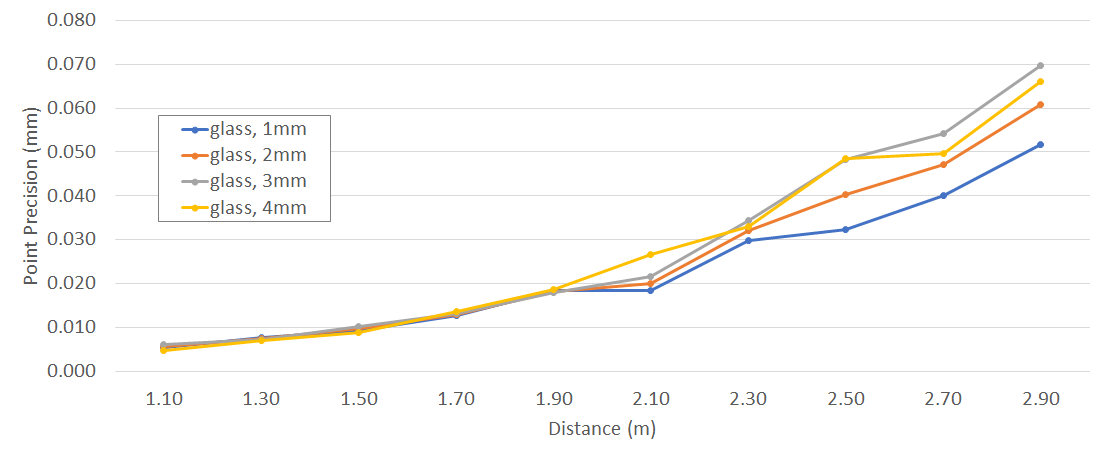

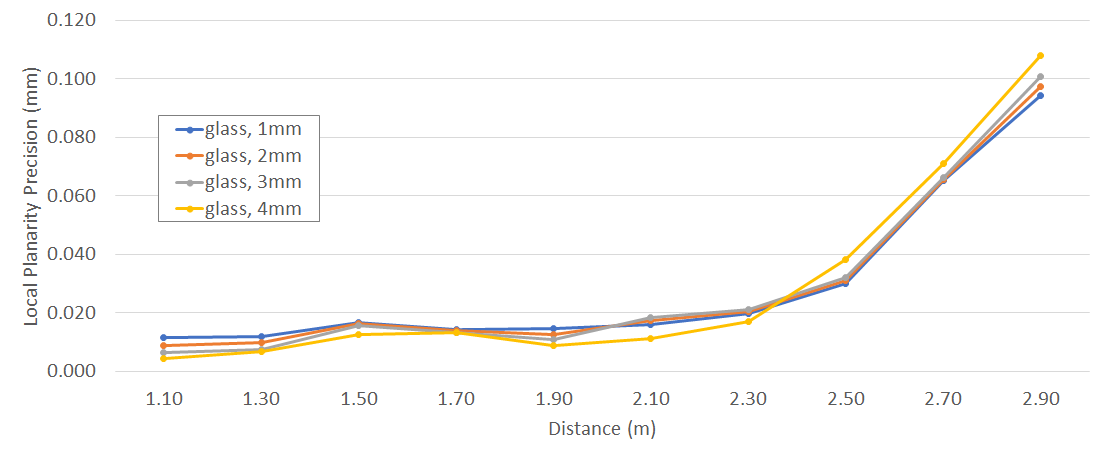

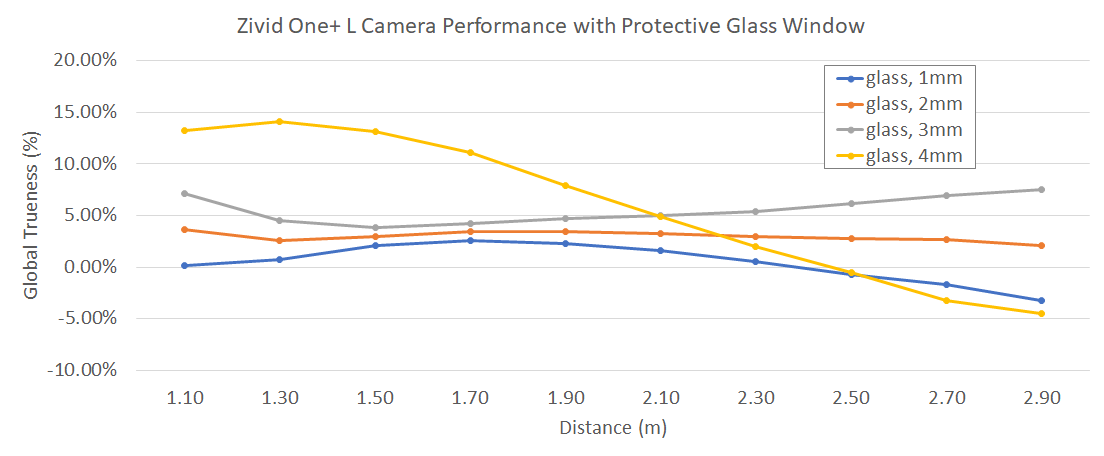

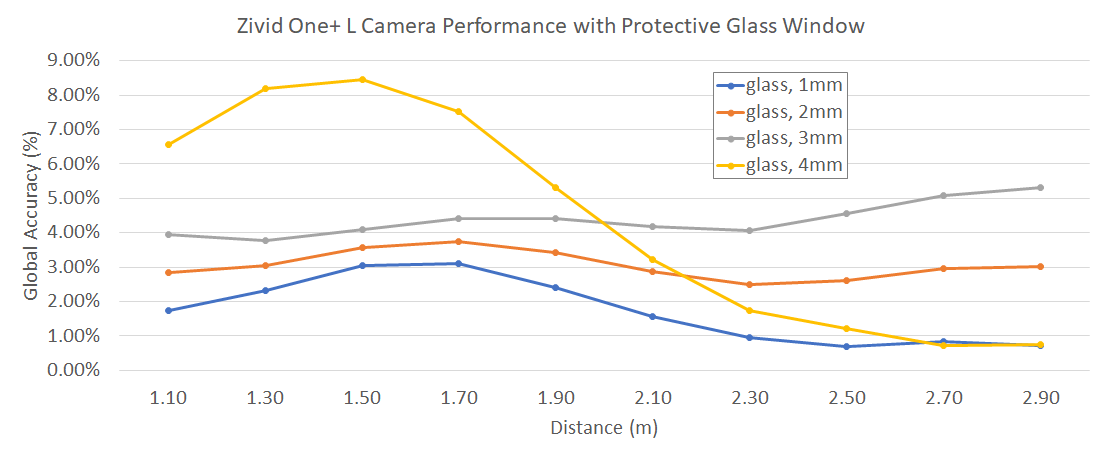

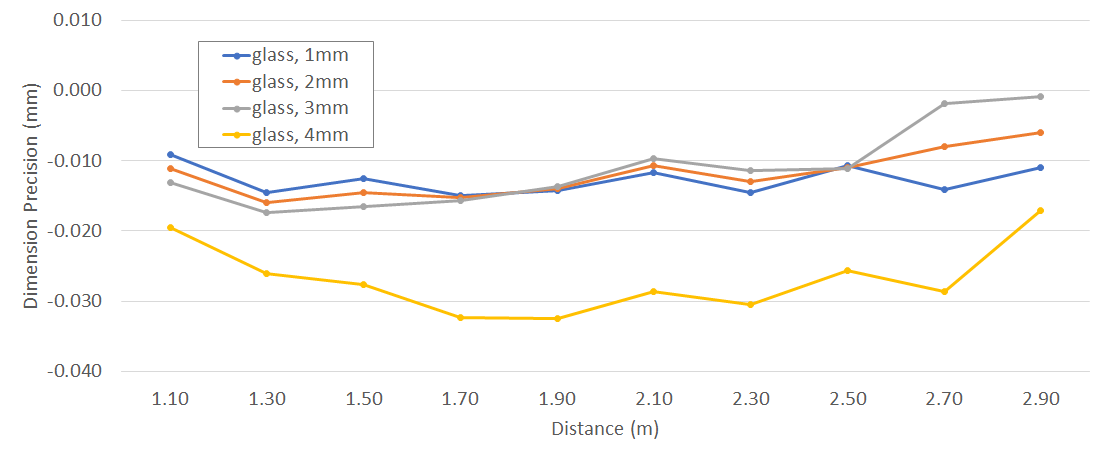

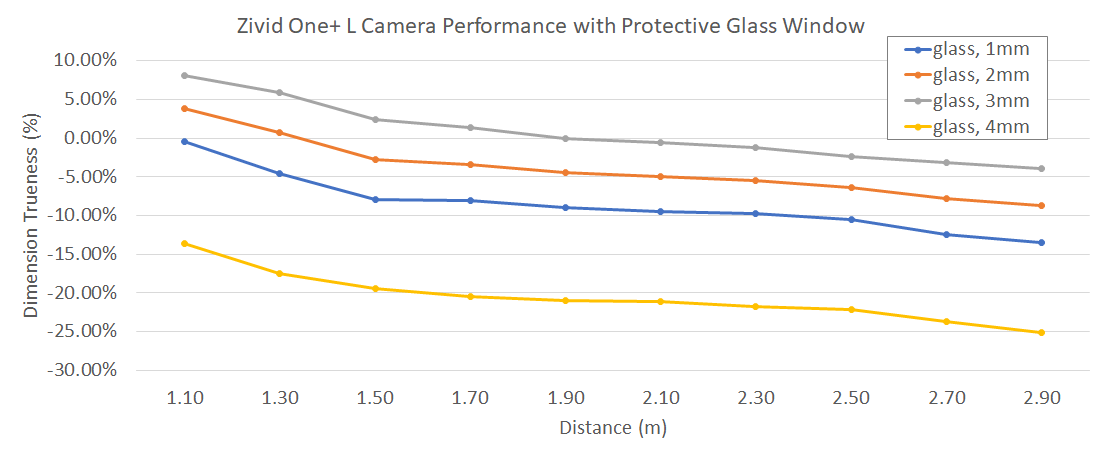

The following graphs show the impact of using various glass thicknesses in front of a Zivid One+ L. Results are compared and presented as a difference relative to not using any protective window. Every graph shows how the performance parameter changes as the imaging distance increases, starting at 1.1 m and ending at 2.9 m. These parameters are defined according to the Zivid One+ datasheet, which can be found here.

Note

Results are shown as a difference relative to not using any protective glass window.

Point precision¶

It can be seen that the point precision error steadily increases with distance (the same is true without the glass), but has no clear dependency to glass thickness. Under most distances and circumstances, these changes should be negligible for the application.

Local planarity precision¶

It can be seen that the local planarity precision error has no clear dependency on glass thickness. The change in planarity precision is contained within 0.1 mm, which is similar to that of point precision, and should also yield negligible effects for typical applications.

Global planarity trueness¶

These tests show how the measured flatness of a plate varies in the presence of a protective window. It can be seen that the variations are contained within ±15%, which is a ±0.075 mm change to a typical planarity flatness in the order of 0.4 mm without protective window. This increases the planarity trueness error to about 0.5 mm and therefore, placing an appropriate protective window will have acceptable implications on the global planarity trueness of the sensor for most applications.

Global planarity accuracy¶

These measurements show how the noise and flatness of a plate vary in the presence of a protective window. The measurements are dominated by the underlying trueness error seen above, with the precision noise added on top. The overall change is contained within ±10% of the existing error without a protective window. For a typical Zivid One+ Large sensor the planarity accuracy is in the order of 0.5 mm. Therefore, a 10% change in this accuracy means that the total error may increase to 0.55 mm. This will typically be an acceptable impact. Note that the relative variation is lower for the global planarity accuracy than for trueness. This is due to the fact that the underlying absolute error is inherently larger for accuracy than for trueness. Thus, variations of similar scale between the two will have a higher impact on the lower value (trueness) than that of the higher value (accuracy).

Dimension precision¶

Repeated measurements of a given dimension of 10 cm show that the variation in the result of those measurements yields a 1σ variation change. This corresponds to less than 35 µm relative to the underlying precision present without protective glass. These numbers are relatively small given the large distances and should have a negligible impact on overall point cloud quality.

Dimension trueness¶

This metric shows how much a given dimension measurement changes in the presence of a front cover glass. As we can see, the variations are below 30% for a large working distance of the camera, with no apparent correlation between the thickness. This means that if an original dimension trueness error of 0.1% was measured without a housing, this error could change to be between 0.07% to 0.13% after introducing a protective window. Such a difference is still acceptable in many applications.

Summary¶

The measurements do not provide enough evidence to prove underlying systematic dependency between the thickness of the glass and camera performance. Impact from imperfect glass quality, such as limited flatness, is a likely candidate to play a dominant factor for accuracy changes.

The presented measurements indicate that the expected change in error should be in the order of <±50%. In systems that depend on high level of reliability, a tolerance level a few times higher than the accuracy of the measuring unit should be employed. From these results we can deduce that an added variation of the error in the order of ±50% is likely to have negligible, or acceptable, impact on the overall system. Thus, the new expected error from the sensor should still be smaller than the total system tolerance.

It is recommended to perform a differential test of the glass quality to confirm that the trueness and accuracy of the camera remain acceptable after installing the protective window.