How to Optimize the Placement of the Calibration Object

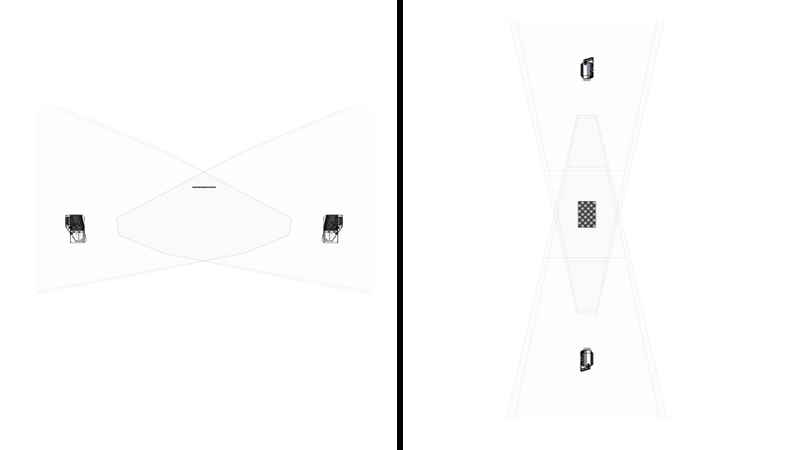

Consider the case where we want to place cameras at 180 degrees from each other. In other words, the cameras face each other. If we place the calibration object in the middle of the FOV we get the following scenario:

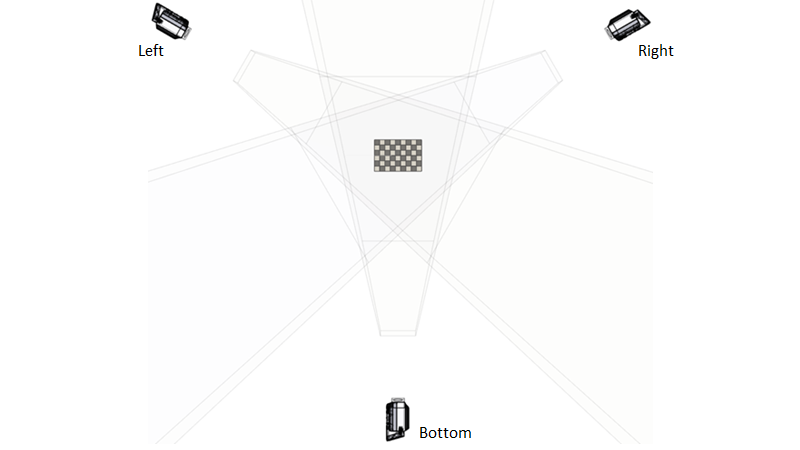

Fortunately, it is possible to reduce the angle limitation by moving the calibration object to one side of the FOV. This way one can still have the calibration object in view, even though the calibration object is aligned with the ZY-plane of both cameras (180 degrees scenario).

In practice, the checkerboard might not be detected even though it is in view. At such steep angles fewer pixels cover the checkerboard, thus it will have a poorer resolution. Thus, in practice, the limitation may be < 180 degrees.

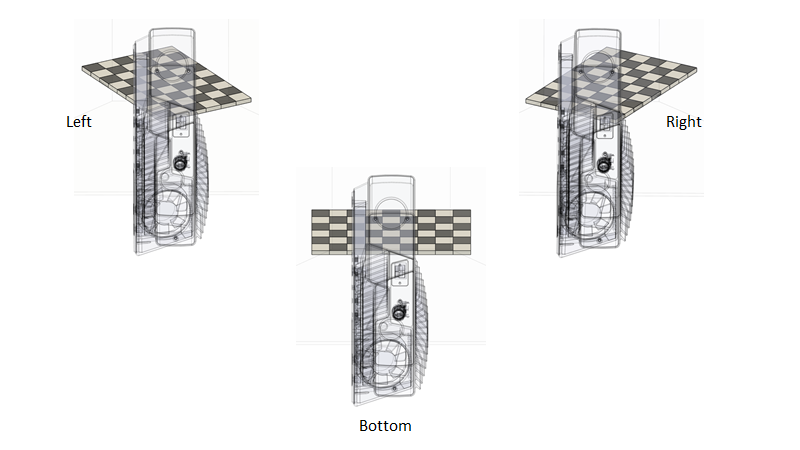

We can extend this concept to more than two cameras. Consider the following use case:

Three cameras

120 degrees angle from each other

Mounted vertically (share YZ-plane)

In this case the checkerboards have an angle that makes it possible to perform calibration.

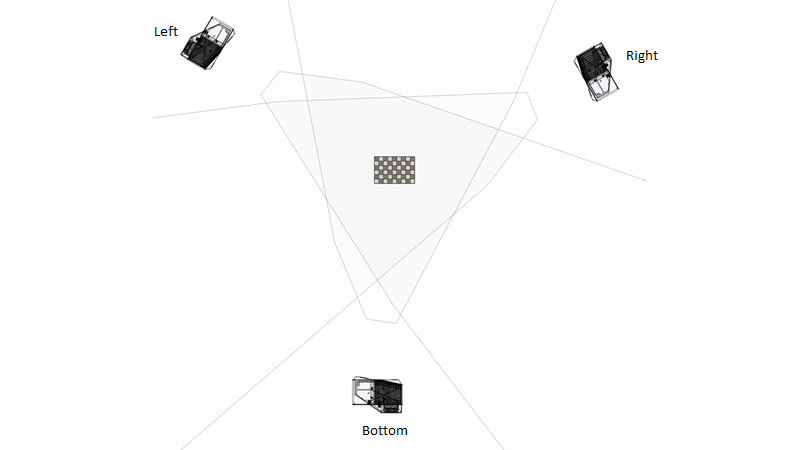

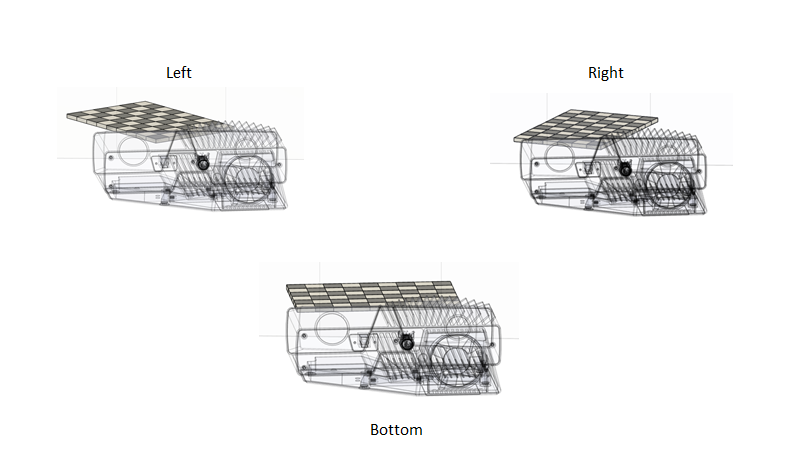

Now let’s assume we tilt all the cameras horizontally in order to have a larger horizontal FOV.

Three cameras

120 degrees angle from each other

Mounted horizontally (share XZ-plane)

The FOV ratio forces us to move the calibration object closer to the common plane. Thus, the angle between the cameras and the calibration object is steeper. If the calibration cannot be performed because the resolution of the checkerboard is too low, or the point cloud quality is not good enough, then we turn to Multi-step calibration.